The business of the company ELEKTRONIKA OSTERMAN IVAN S.P. is the production of printed circuitboards, which we have been working on for more than 30 years. During this time we have accumulated an abundance of experience and exceeded the expectations of many customers. We cooperate with many long-term business partners, both from the domestic and foreign markets, who keep returning mainly because of the quality printed circuitboards.

We produce one-sided and two-sided printed circuit boards. We use materials exclusively from the best quality suppliers who fulfil the UL certificate. We use materials from the companies Isola, Nanya and KingBoard.

We are distinguished by speed, quality and reliability. We guarantee high quality products with modern production equipment, rigorous final inspection of printed circuitboards and tracking of the latest technological processes, as it is a priority for us to ensure that manufactured printed circuitboards meet all the requirements of our customers.

We offer the rapid production of quality prototypes of printed circuitboards. We always stick to agreed deadlines and know how to adapt to the wishes and needs of our customers.

We are specialized in the field of manufacture of printed circuit boards with high copper thickness.

The company Elektronika Osterman Ivan s.p. is producing printed circuit boards according to a unique chemical process that allows us to produce circuits with a maximum copper thickness of 250 μm. This process achieves that the printed circuit boards are finally made with identical application of copper both on the entire surface and in holes. This type of printed circuit board can withstand significant electrical loads.

Because we strive for the highest quality of our printed circuits, we produce them exclusively from materials of the highest quality.

UL certificate for the highest quality of printing circuit boards

In 2018 we obtained a quality

UL certificate. In this way, we can offer our customers the production of printed circuit boards that are equipped with this certificate. This ensures that the product complies with scientific standards of safety, quality and protection.

General on printed circuit boards

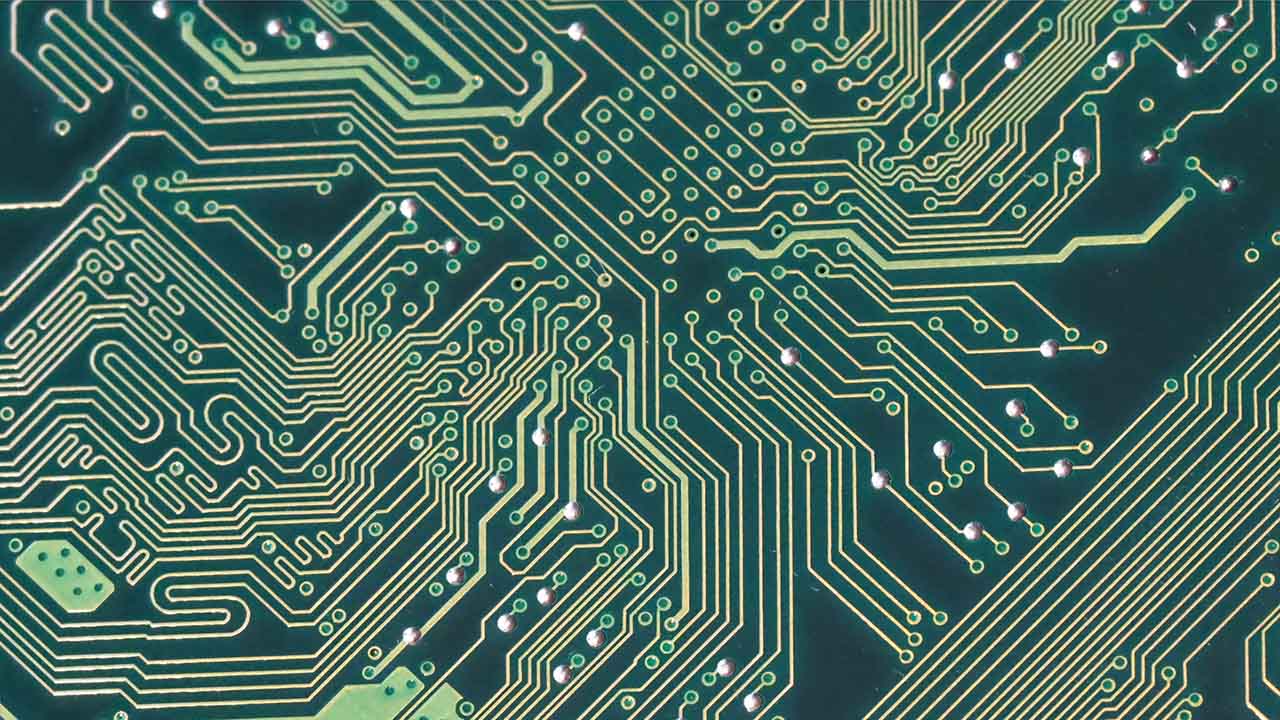

If we open any device, we will find one or more plates in it for which the name of the printed circuit board has been established. These are treated panels on which different electron elements of the THT type (components through the hole) and SMD (surface-mounted components) are installed, which are connected by means of copper bindings.

The basic material for the manufacture of printed circuits consists of three layers. The middle layer is called an insulator and is non-conductable. Its thickness may range from 0,2 mm to 3,2 mm inclusive. It consists of a material called a vitroplast, made of fiberglass. The centre layer is surrounded by one or two layers of copper foil. The most common copper thicknesses are 18, 35 or 70 μm and less common are 12 and 105 μm. There are several companies on the market that produce all the necessary materials for the manufacture of printed circuitboards of the highest quality.